- Zhengye Technology has more than 20 years of experience in X-RAY equipment. Welcome to consult

- Email: info@zhengyee.com

Fully automatic X-ray inspection machine

- Classification:Battery XRAY, Products

- |

- Distribution Date:04/21/2025 pm3:23

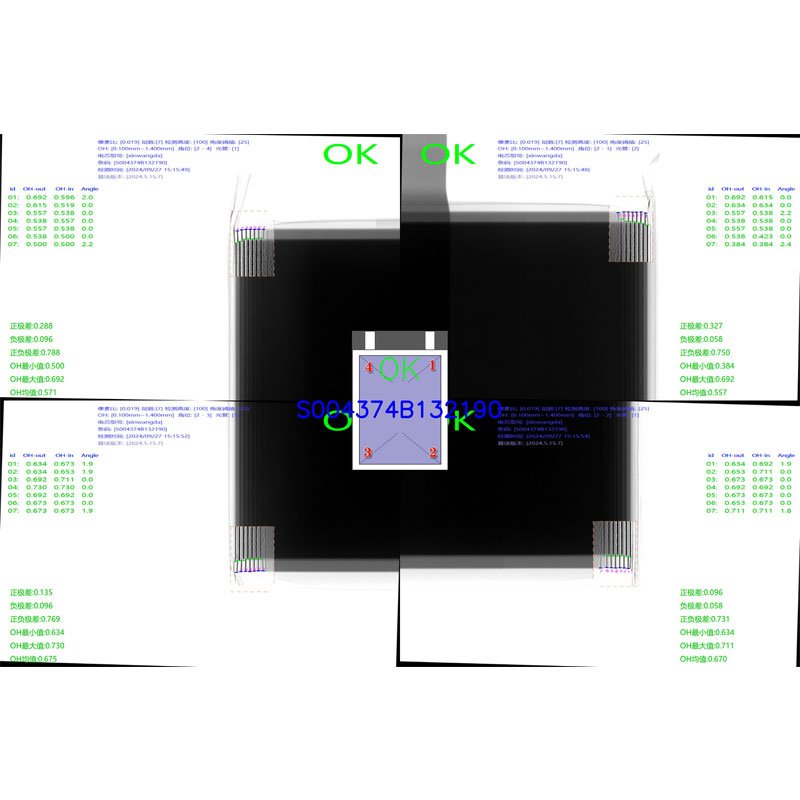

X-ray inspection machine XG5500 One imaging system and two sets of manipulators perform online inspection and analysis, and conduct online fully automatic inspection of square polymer soft-pack batteries or finished batteries.

- Brand:Zhengye

- Model: XG5500

- Light tube voltage:90-130kv

Product Details

X-ray inspection machine Application introduction:

X-ray inspection machine XG5500 One imaging system and two sets of manipulators perform online inspection and analysis, and conduct online fully automatic inspection of square polymer soft-pack batteries or finished batteries. The device emits X-rays through the X-RAY generator, which penetrate the inside of the battery. The imaging system receives the X-rays and takes pictures. The image is processed and automatically measured and judged through relevant software to determine good and bad products, and the bad products are selected. The front and back ends of the equipment can be connected to the production line.

X-ray inspection machineProduct Features:

1. Rich software functions:

(1) Automatically measure the alignment of the positive and negative electrodes of the battery, and count the maximum, minimum, average, positive electrode difference, and negative electrode difference;

(2) Automatically judge good and bad products, and automatically sort bad products;

(3) Scan code function, record battery codes, track battery test results one by one, and upload them to the terminal server.

2. High detection efficiency: One set of imaging system and two sets of feeding manipulators operate alternately to realize online detection and analysis, with high efficiency, daily inspection of more than 30K, suitable for large-scale full inspection of square polymer soft-pack batteries or finished batteries.

3. Production line docking: The inlet and outlet can be docked with the production line.

4. Fast model changeover and debugging: Different models of batteries can be changed and debugged quickly, and the replacement time is within 10-30 minutes.

5. Safety and environmental protection: The entire equipment is safety interlocked, with triple protection functions, and any part of the body surface meets the safety radiation standards.

X-ray inspection machine Inspection object:

Object: Inspection of the alignment of square polymer soft-pack cells and positive and negative electrodes of finished batteries.

| Battery length | 50-150mm |

| Battery Width | 30-100mm |

| Battery thickness | 2-12mm |

| Battery winding layers | ≤13 |

X-ray inspection machine Technical parameters :

项目 规

| Light pipe | Light tube voltage | 90-110KV |

| Light tube current | 89-455uA | |

| Focus size | 5um | |

| Cooling method | Forced air cooling | |

| Imaging System | Field of view | ф100mm/130x130mm |

| style | Intensifier/Flat Panel Detector | |

| X-CCD分辨率X-CCD resolution | 1024*1024Pixels | |

| quantity | 1 set | |

| Detection accuracy | Repeatability test accuracy | 60um |

| efficiency | Detection efficiency | ≥30ppmAny diagonal |

| Error rate | ≤2% | |

| Missed Detection Rate | 0% | |

| Product quality | ≥99.5% | |

| Safety Standards | International Radiation Safety Standards | ≤1μSV/hr |

| Other parameters | computer | 500G22″ widescreen LCD display/I5 processor/4G memory/500G hard disk |

| Host size | 2800*1550*1850mm | |

| power supply | AC380V/50HZ | |

| Temperature and humidity | 25 ℃±3 ℃ RH50%±10% |