- Zhengye Technology has more than 20 years of experience in X-RAY equipment. Welcome to consult

- Email: info@zhengyee.com

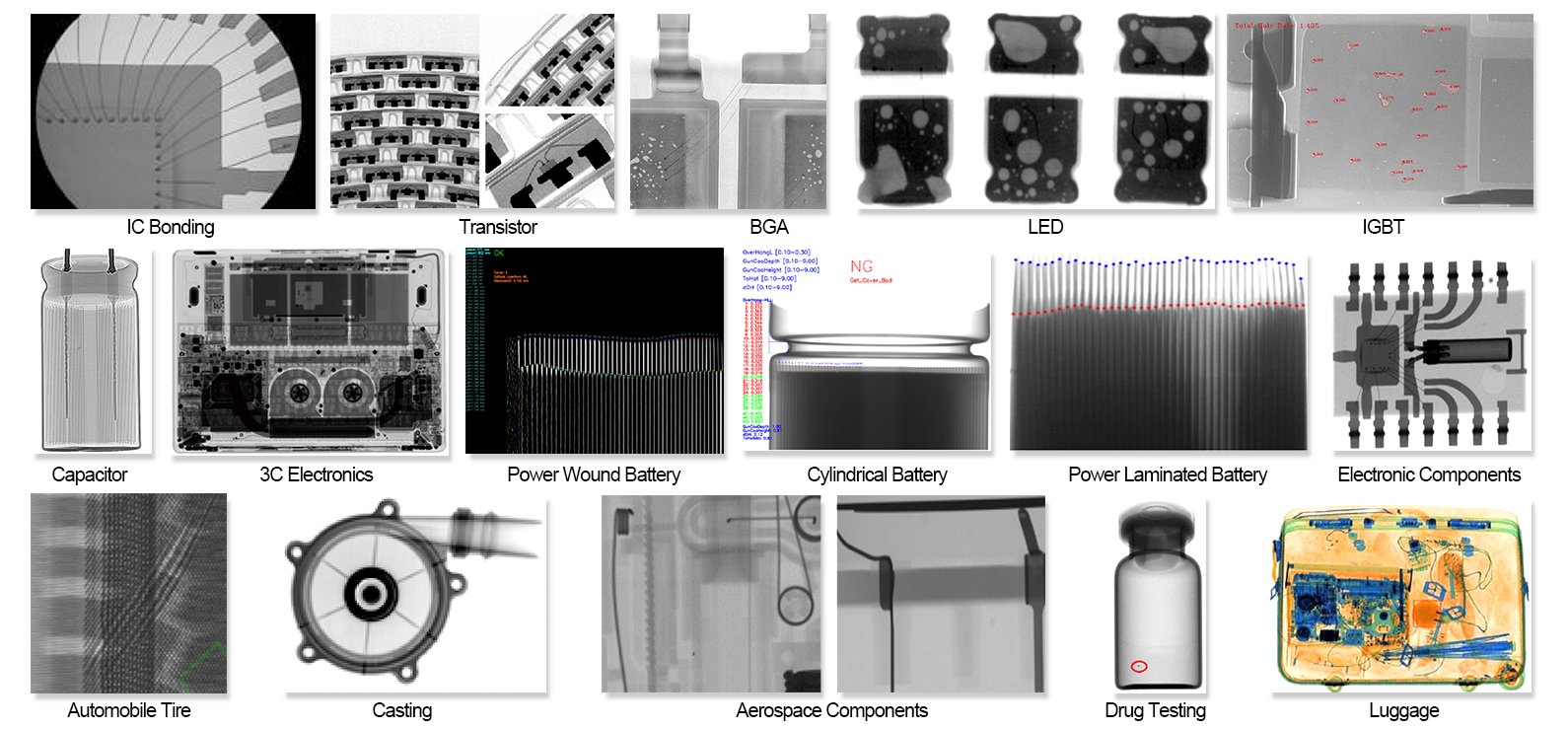

XRAY testing equipment can detect a wide range of products, including but not limited to the following categories:

1. Electronic components: such as IC chips, PCB printed circuit boards, PCBA/SMT/BGA solder joints, lithium batteries, IGBT semiconductors, LED/LCD, etc.

2. Lithium batteries: detect internal defects and effectiveness of batteries, such as positive and negative poles, internal structures, etc.

3. Semiconductor products: such as integrated circuit chips, various components, etc., can detect their internal structures, packaging processes, etc.

4. Metal castings: such as hardware castings, automotive parts, pressure vessels, pipelines, etc., can detect internal welds, cracks and other defects.

5. Plastic materials and parts: can detect cracks, foreign matter and other defects inside plastic parts.

6. Auto parts: such as aluminum castings, tire wheels, etc., to ensure the quality and safety of parts.

7. Other industrial products: such as ceramic products, cables, fixtures, etc., can detect internal cracks, foreign matter and other defects.

In addition, XRAY inspection equipment can also be used to detect the welding quality of products, such as identifying BGA welding defects such as empty solder joints and cold solder joints, as well as the structural dimensions and wear conditions of products. In general, XRAY inspection equipment is widely used in the industrial field and can help companies improve product quality and safety.

- X-ray detection equipment XG5010A: equipped with intelligent AI ultra clear algorithm

- Zhengye Technology held a summary and commendation meeting for the first quarter of 2025

- Application and advantages of XRAY detection technology in chip manufacturing

- Using XRAY scanning technology to improve semiconductor chip quality control